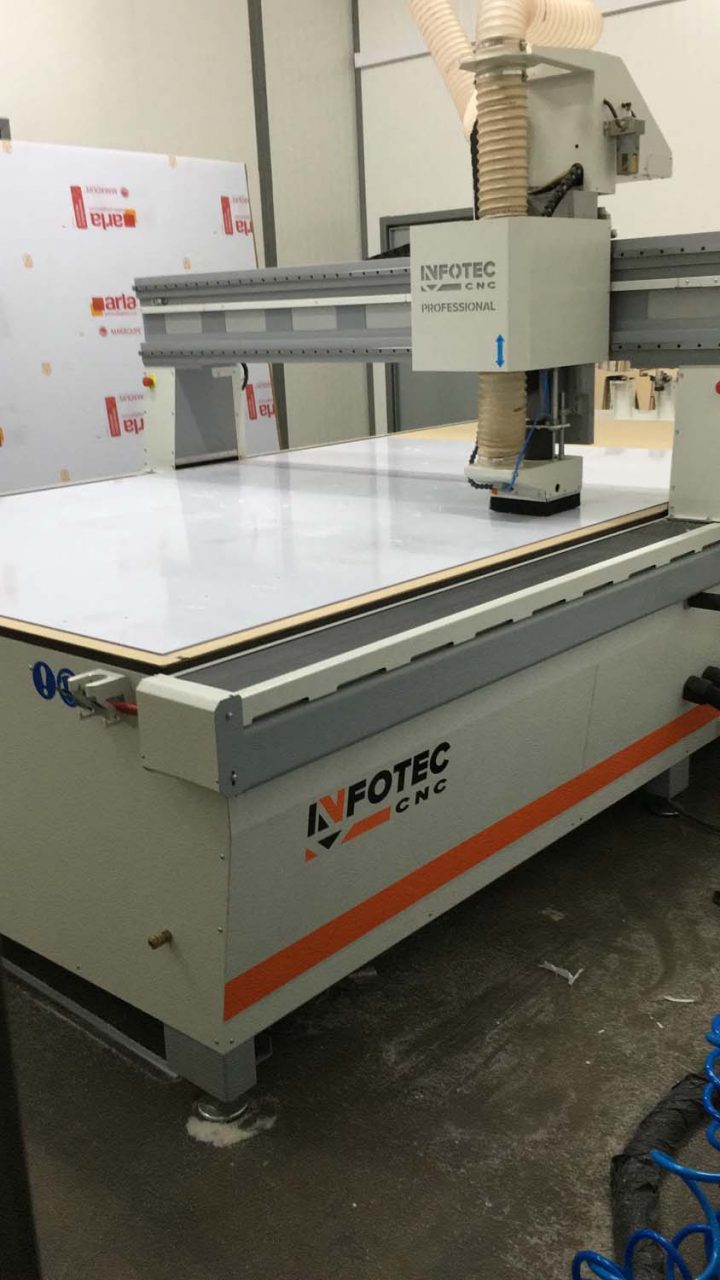

The working area of the 3 – axis milling plotter is 410 x 210 cm.

Materials milled

- wood-based products – plywood, MDF, HDF, chipboards, laminated boards, OSB

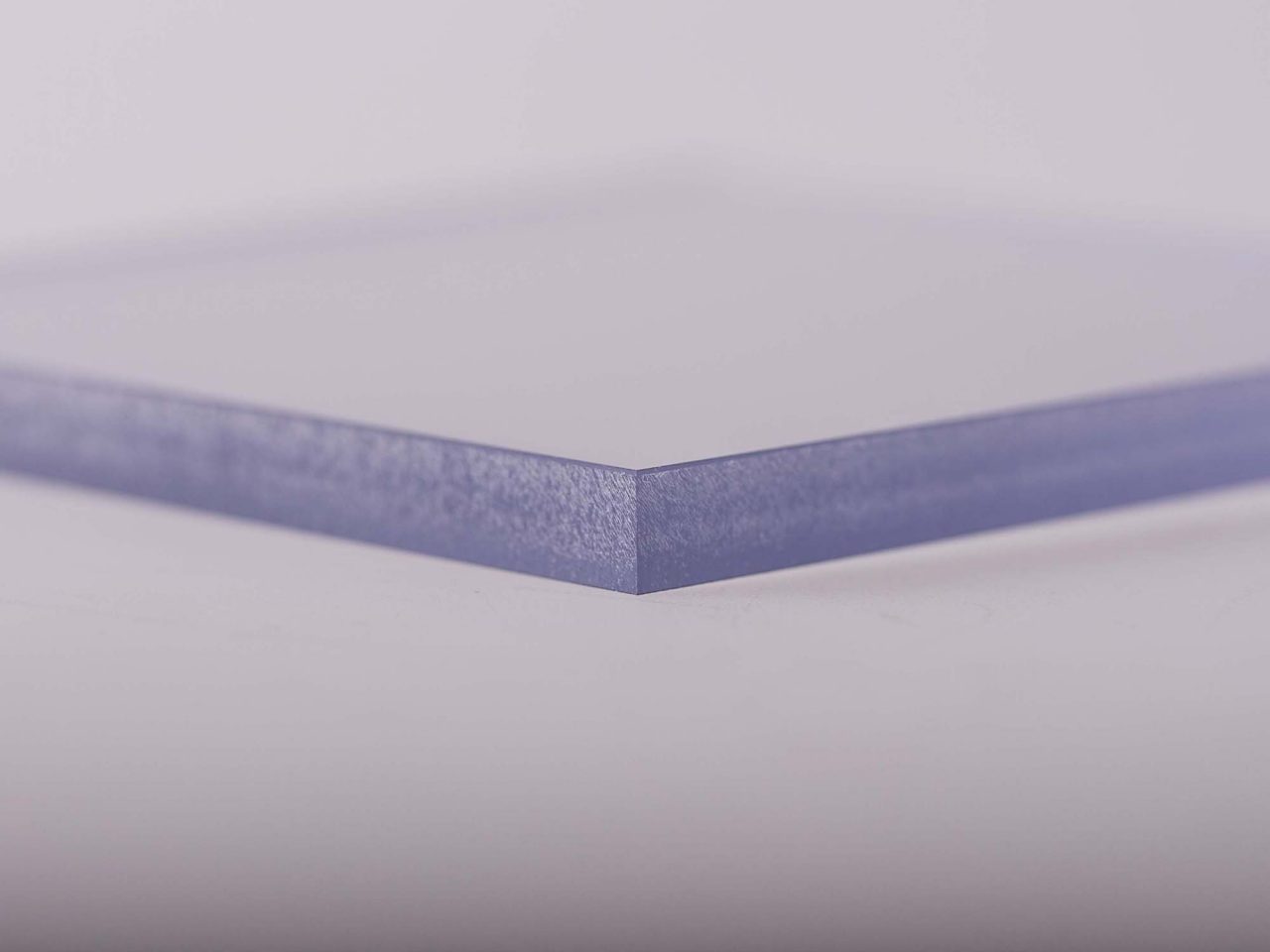

- plexi

- PVC foamed and hard

- all composite materials, e.g. Dibond or AluCore type

- polycarbonate

- polyethylene

- polypropylene

- HPL laminate

- polyurethane foams, sponges,

- technical plastics

Milling CNC characteristics

CNC milling machines are machines that allow machining a wide range of materials by machining. For work, cutting tools are used – cutters, thanks to which you can quickly format the material (nesting), drill, hole, finish the edges, cut any shapes and mill 3D shapes – packing fillings.

In our machine park we have a milling center with high power spindle and a vacuum table, which enables fast and accurate production of elements for the needs of many industries. In addition, we also have a milling plotter with a T-grooved table, allowing traditional clamping of the workpiece on the table.

The project delivered to us in the form of a CAD file is processed into the machine language along with the selection of appropriate tools. The machining guarantees high precision and repeatability. We use the highest quality tools, and the machine parameters are selected to achieve the desired edge finish quality and the fastest possible processing speed.

The use of CNC milling

Milled elements are used in the furniture, shipbuilding and machine-building industries. Thanks to the 3-axis milling machine and the use of a wide range of modern cutting tools, it is possible to make various types of elements as well as parts and details.