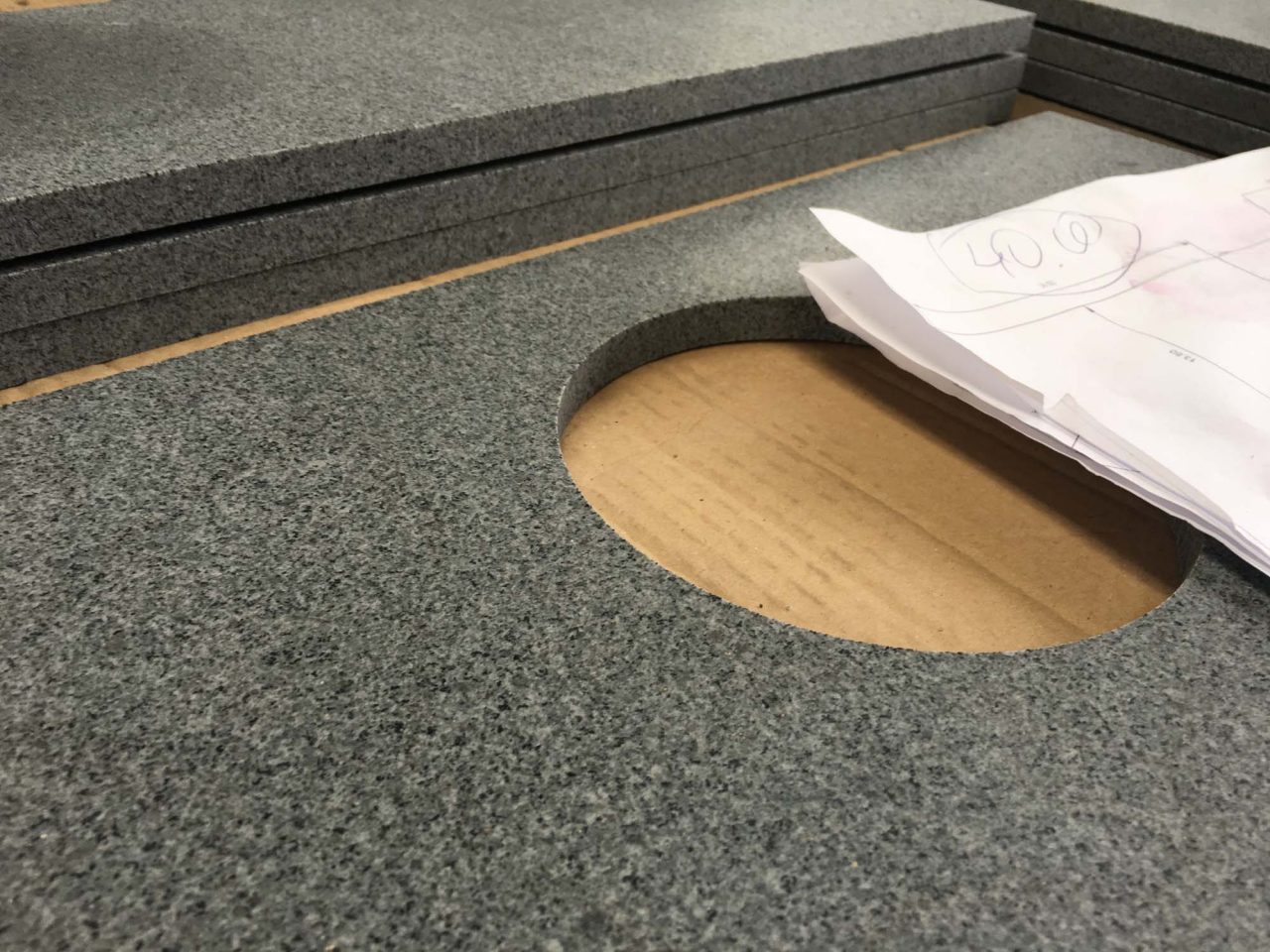

The maximum thickness of a plate treated with our machine is 50 mm.

The working area of the water cutting machine – WaterJet is 150 x 300 cm.

Materials processed with Waterjet

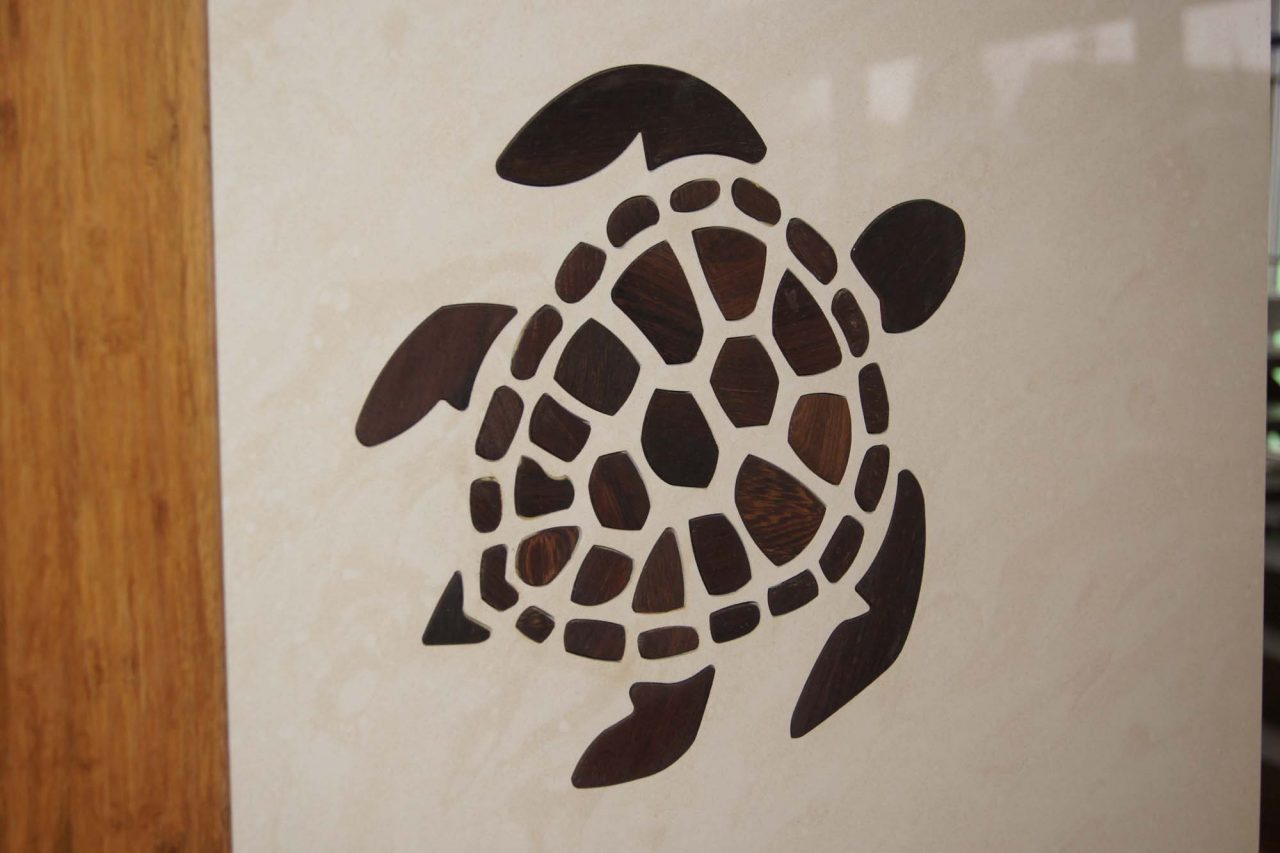

- natural stones (mosaics)

- granites

- marbles

- sandstones

- wall and floor ceramic tiles

- gres tiles

- gypsum tiles

- structural and tool steel

- aluminum

- bronze, copper, brass

- high-nickel alloys

- titanium

- molybdenum

- glued, laminated, rolled, armored glass

- glass wool and mineral wool

- mirrors

- clad sheets

- plastics

- composites

- fabrics

- epoxy resins

- rubbers (e.g. polyamide, polyurethane)

- all types of seals and fricion materials

- foams, sponges

Important information about the materials provided by the clients

Water cutting technology is completely safe for your materials. The only reasons for cracking / crushing of glass / tiles, etc. are material defects, e.g. stress, improper burning, etc.

Please take into an account the fact that several tile pieces more should be considered for possible losses!

Waterjet CNC characteristics

Waterjet is a technology that uses a high-pressure water jet to precisely cut a wide variety of materials. Computer controls the processing of the material and it’s cutting process based on a project made in the CAD program. Waterjet technology has many advantages that set it apart from other cutting techniques.

Waterjet cuts materials of various thicknesses, including metal, plastic, glass and ceramics. The use of this technology in the production of elements gives the possibility of making precise cuts of any shape, while maintaining high quality of cut edges and a lack of internal stress in the processed elements.

Waterjet cutting means:

Other materials and thicknesses – we need to make a test cut.

- the use of technology only for flat surfaces of workpieces;

- cutting through the entire thickness of the material.

- cutting hard materials of high thickness up to 50 mm;

- precision, high quality of cut edges;

- does not cause microcracks, stresses or changes in thermal reactions in metals (which is important in the case of tool or hardened steel);

- serial and individual use for various types of materials;

- short delivery time – flexible production option;

- small cutting width – stream – 1 mm;

- it happens that this is the only way to get the desired element;

- satisfactory cost compared to other methods – lower than traditional methods and laser cutting (in this case, above 5mm thick).

Use of WaterJet cutting

Cutting with high-pressure water is very popular in heavy industry, textile, glass, paper, wood, electronics and even food and aviation industries. This technology has permanently entered almost every branch, also for economic and ecological reasons – it is safe for the environment and requires little energy. No dangerous waste (any abrasives used are chemically inactive and its origin is natural and recyclable);