The CNC laser cutting plotter uses a focused beam of light with a high power 200W controlled by a computer that controls the cutting or engraving process based on a project made in the CAD program.

The working area of the laser machine is 120 x 240 cm.

Materials processed with a CNC laser

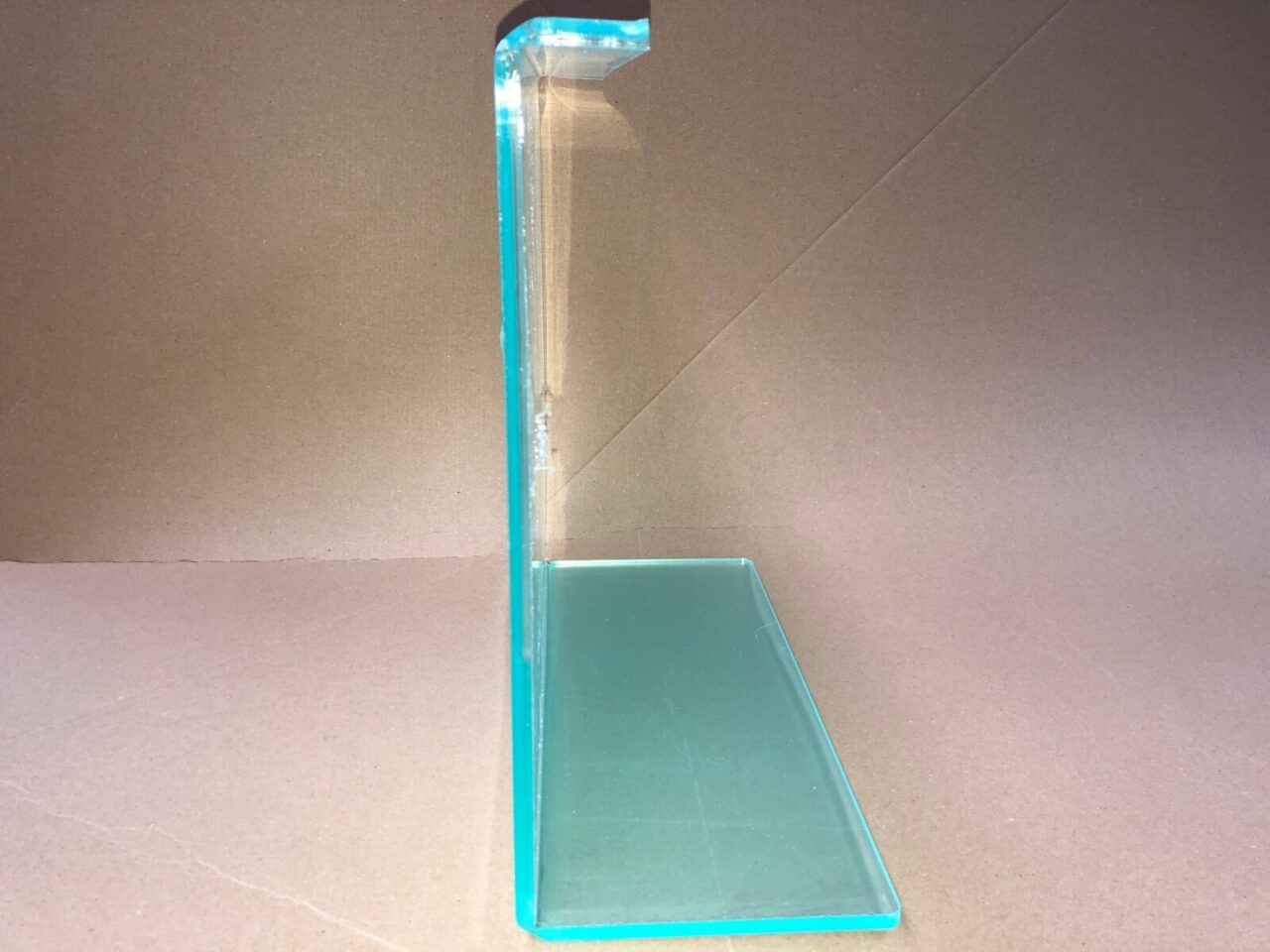

- plexiglass – acrylic glass

- wood-based products e.g. plywood

- cardboard

- different types of foam

- PET

Advantages of laser cut

Laser cut characteristics

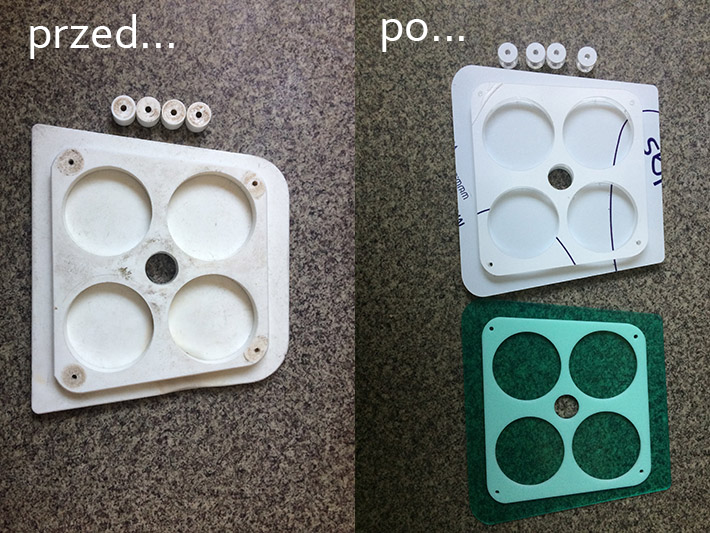

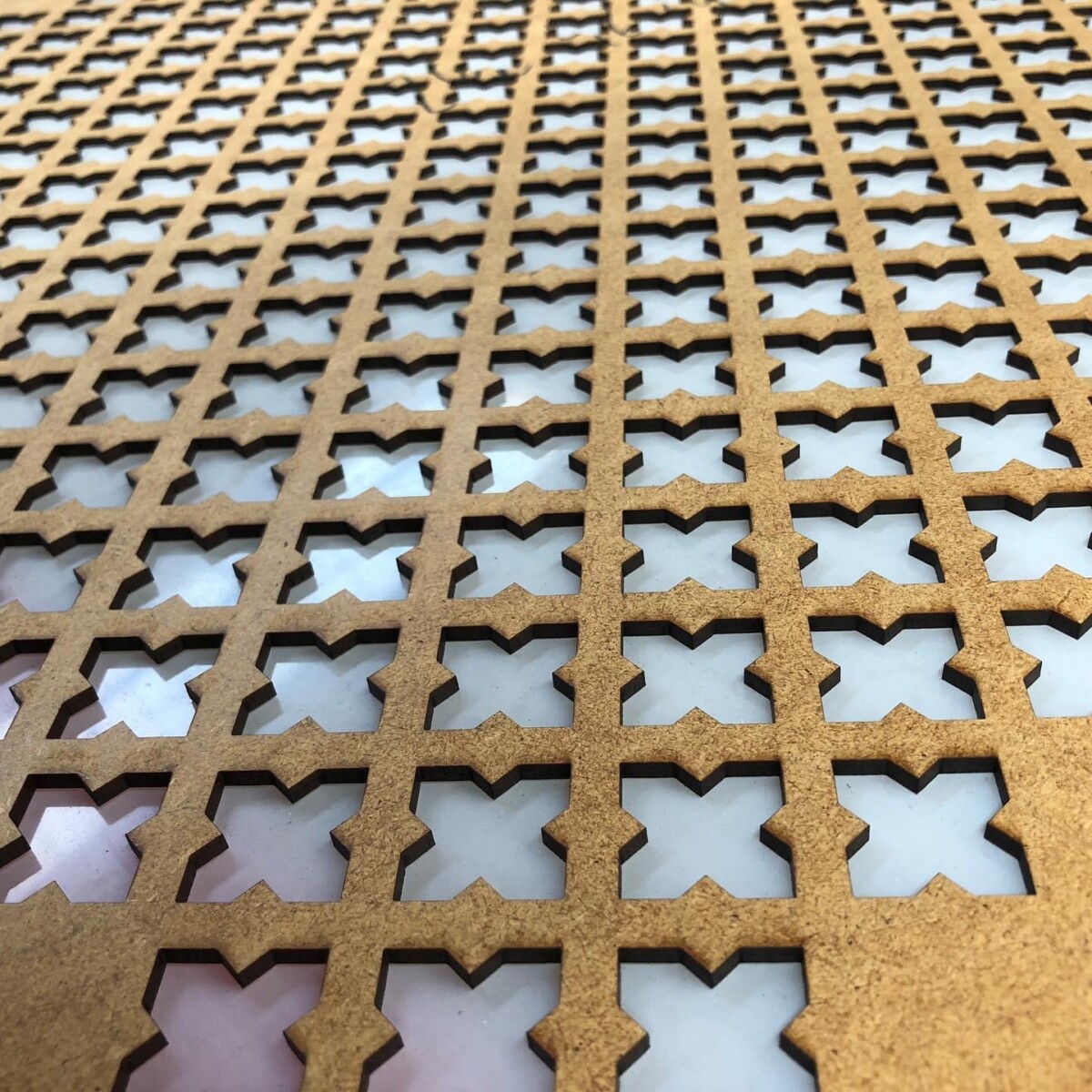

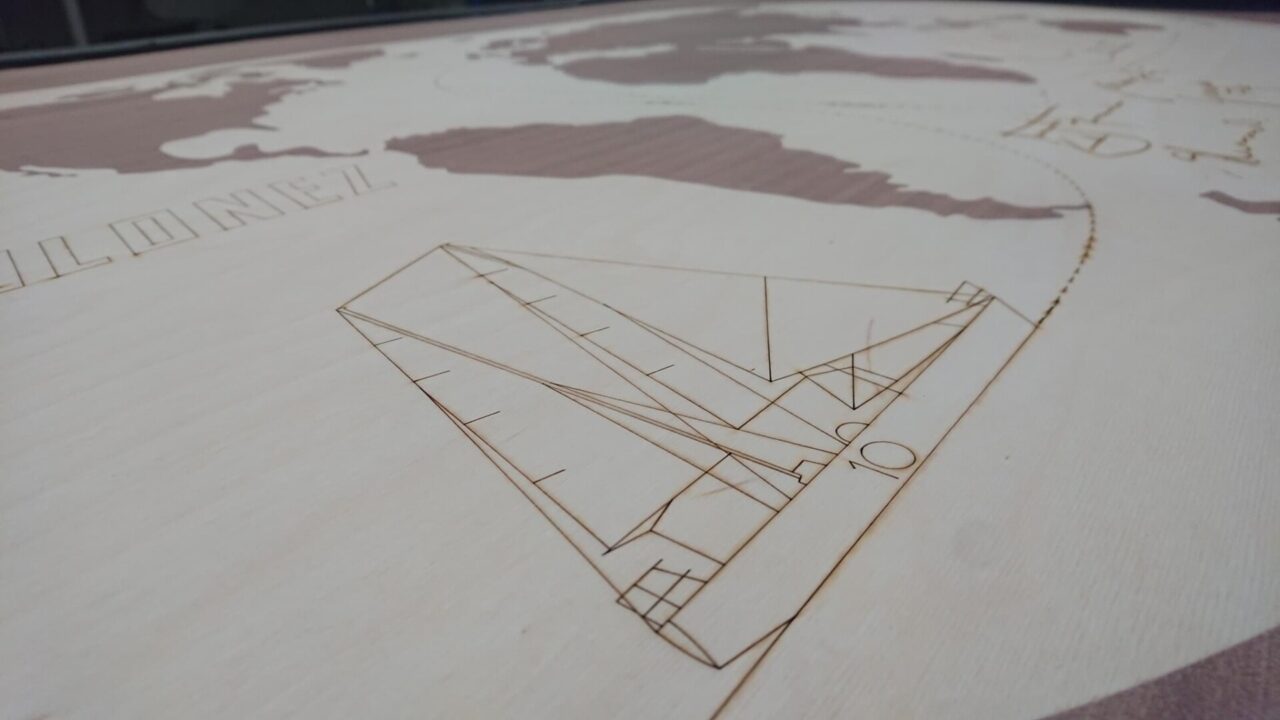

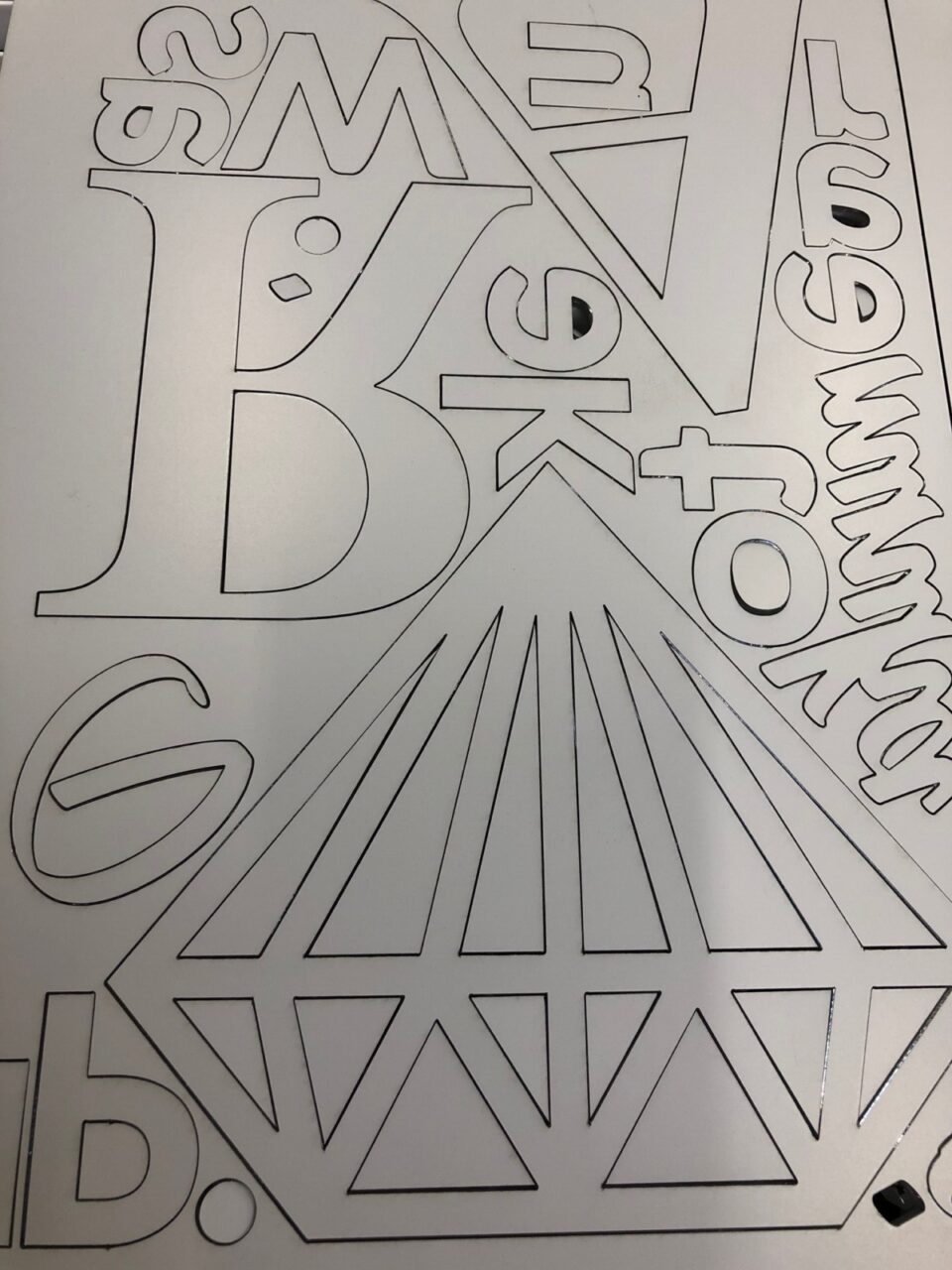

Laser technology cuts plastics, wood or paper very precisely and maintains the cutting edge very specific, depending on the material type. Plexi, for example, melts – giving the effect of glossy edge surface. The laser head can move on any contour, cutting or engraving material using very complex shapes and patterns, and acute angles.

The cutting width is very small and allows us to cut very small elements and complex patterns and shapes.

Laser cutting is a modern machining method with similar parameters as classic mechanical machining. The main difference lies in the cutting factor used, which in the case of laser cutting is the laser beam. In practice, it looks like the generated high power laser beam falls on the material and causes its evaporation. Depending on the needs, it is a partial evaporation during engraving or complete while cutting.

The use of laser cutting

Laser cutting and engraving is used in many industries where high accuracy of manufactured elements is needed, in heavy industry, as well as in printing.